If you’re thinking of installing an elevator in your home, now is the time! Home elevators are safe and efficient, which makes them the perfect choice for people who have trouble moving up and down stairs or who want some added luxury in their house.

There are many different elevator types to choose from, and each type has its own advantages. This guide will discuss each type of home elevator, what sets them apart from other types, and the benefits of installing each. Keep reading to see which residential elevator may be right for your needs.

Hydraulic Elevators

Great for: a quiet, smooth ride and spaces with low ceilings

Hydraulic elevators are what most think of when they think of elevators. They are driven by pumps and a motor and use hydraulics to ascend and descend. They’re one of the quietest and smoothest types of elevator. They can also be installed in spaces with low ceilings because of the low overhead requirement.

Genesis hydraulic elevators are fitted with a compact drive cabinet, a submersed hydraulic pump motor, and aircraft-quality steel suspension cables. These premium materials make your ride safe and quiet. These elevators are complex in design but relatively simple to install; they also allow for multiple choices in terms of speed and operation because of their two-speed control valve and adjustable pit depth.

Pneumatic Elevators

Pros: low-maintenance and environmentally friendly

Pneumatic elevators are friendly to the environment and offer an aesthetic quality no other elevator can offer. They feel luxurious because of their transparent visage and smooth ride. Unlike traditional elevators, these elevators use pneumatic technology to generate lift. That means there are no lubricants, gasses, or oils used in their operation.

Because they’re not as mechanical as traditional elevators, they also require little maintenance and run for greater durations than ordinary elevators. There are fewer moving parts in pneumatic elevators than any other type of elevator.

Counterweight Elevators

Great for: limited space, no mechanical room needed

Similar to pneumatic elevators, counterweight elevators use little machinery. However, instead of using the natural power of air and gravity to operate, counterweight elevators use a series of counterweights to propel themselves upwards and downwards. These elevators are smaller than most because there’s no need for a machine room.

There’s also no hydraulic fluid required because the elevator will operate without the constant need for hydraulic movement. These elevators are powered by a small electric motor and an efficient rail system; they also use a counterweight frame and car sling to provide stability and comfort. These elevators require higher ceilings than a hydraulic elevator, but not as much space in general.

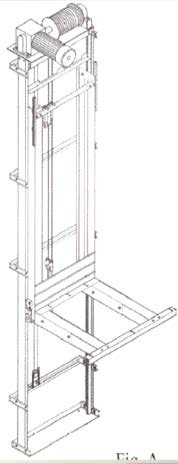

Winding Drum Elevators

Great for: coastal locations, or where there is a risk of potential flooding

One of the more unique types of elevators, winding drum elevators use a simple process of operation. A helical beveled gear-motor assembly is mounted at the top of two guide rails. This gear-motor raises and lowers the elevator using two elevator-grade steel cables and is controlled electronically through the use of a variable frequency electronic drive system.

This setup ensures a quality of ride in terms of sound, stability, and comfort. The elevator is also locked electronically and can be opened with the use of a gate switch, which further ensures safety of all passengers inside. These elevators are often installed on the coast, where greater threat of flooding exists.